Transforming Manufacturing Capability Through Strategic Partnership

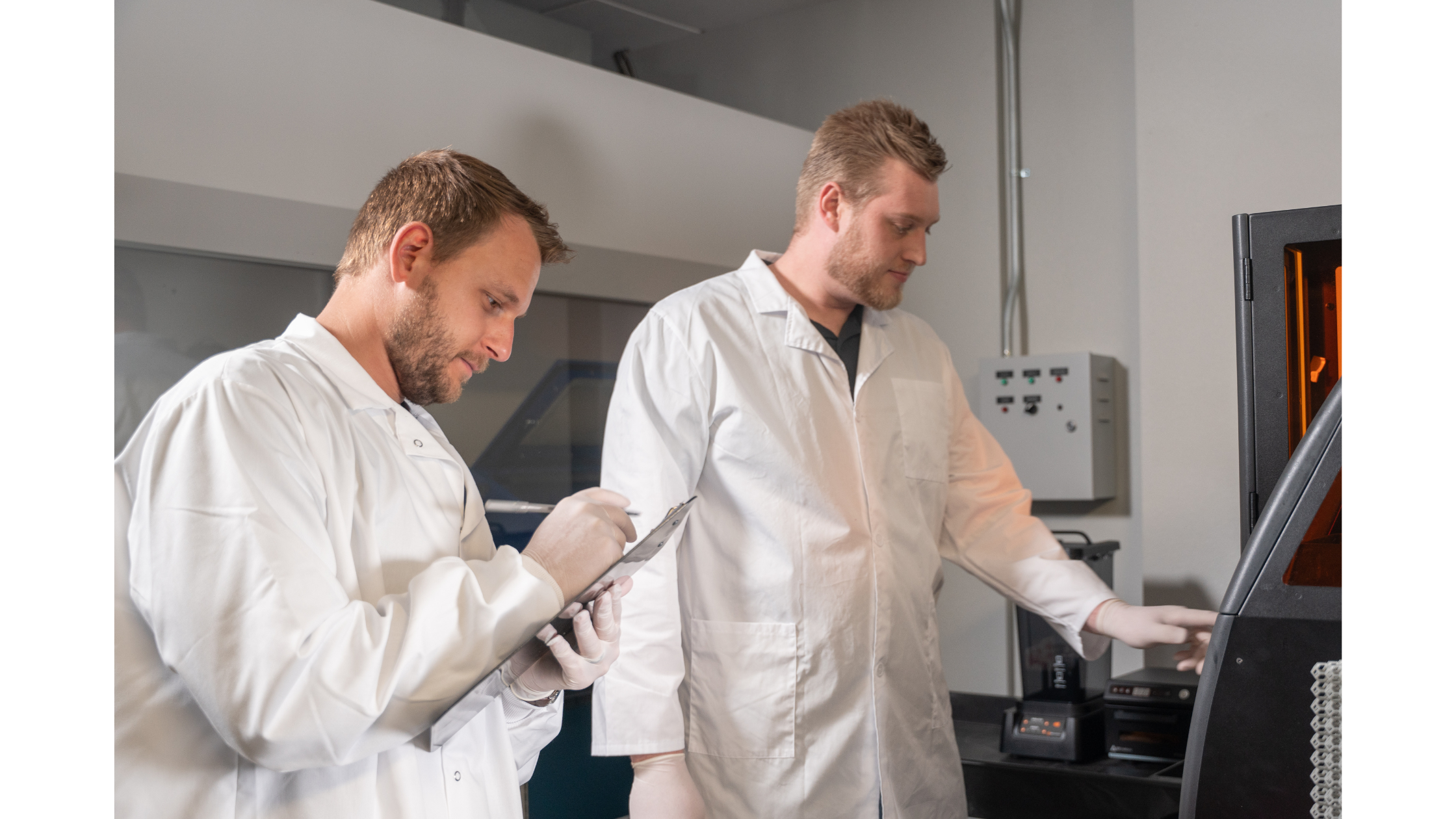

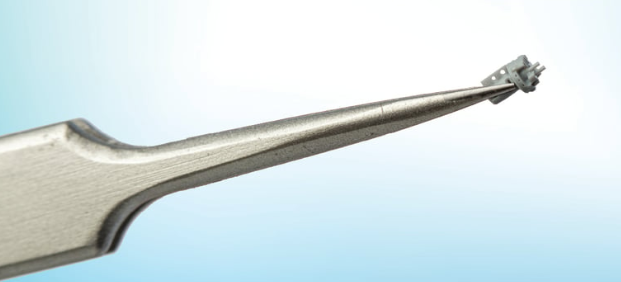

When your core business has been thriving for 50+ years, but evolving customer demands reveal a critical capability gap, incremental improvement isn't enough. Thermo Fisher Scientific faced exactly this challenge: a booming high-volume plastics manufacturing business that couldn't serve customers asking for custom, low-volume components. Working with B9Creations, they built an entirely new production capability, the first AM...