Companies across the chemical manufacturing, research, engineering, and educational sectors are using B9Creations’ ultra-precision digital manufacturing solutions to bring breakthrough ideas to life. Today, B9Creations partners with 80+ of the top universities and research facilities across the globe.

Colleges & Universities prepare students for future-proof careers.

Research Labs & Engineers bring breakthrough ideas and concepts to life.

Chemical Companies Develop novel materials tailored for additive manufacturing.

Technical Schools & Fabrication Labs incorporate industrial-grade 3D printing into fabrication labs and maker spaces.

We Power Your Research So You Can Change Our World

B9Creations’ technology has been featured in 180+ peer-reviewed journals, being used for research such as:

- Microfluidics

- Oncology, Stem Cell, and Biomedical Research

- Drone Development and Robotics

- Micro-Circuitry and Mechanical Engineering

- Materials Science and Development

- Geology

- Physics

- Art & Design and Business School Prototypes

- Faculty Research and Student Projects

- And More

Challenge:

CellField Technologies, a biomedical research company founded by a South Dakota Mines research team, needed to find a cure for osteoarthritis, but there was no effective way to study the cells that caused it.

Solution:

Challenge:

Challenge:

South Dakota Game, Fish and Parks needed to track the population growth rate for bobcats to help with harvest, models, and population viability. And to do that, they needed the bobcat kitten survival rate, which had never been published before.

Solution:

Instead of using implanted trackers, which can lead to injury, migration to other areas of the body, and even fatalities in some instances, South Dakota Game, Fish and Parks is 3D printing collars that hold tracking devices and expand as the juvenile bobcat grows.

“Before these 3D printed expandable collars, the only solution for kittens and growing animals are implants, but those have a small range, risk of adverse health effects, and the transmitter will always be with the animal. These 3D printed collars made a huge difference – and could be used on a lot of other species as well.”

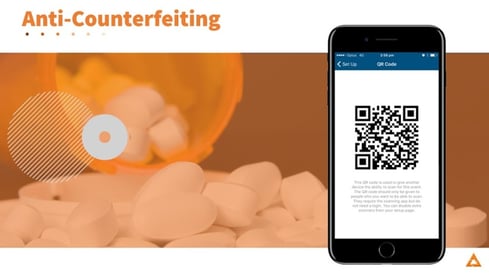

Challenge:

Counterfeiting creates an enormous drain on the global economy and can negatively affect virtually every economic sector. Not only is currency a target for counterfeiting, but also pharmaceuticals, legal documents like bank notes, high-priced art, historical artifacts, consumer electronics, and even wearable apparel and accessories.

Solution:

The Center for Security Printing and Anti-Counterfeiting Technology (SPACT), powered by the hands of research facilities in three South Dakota universities using B9Creations technology, has revolutionized the way that security-end products are handled. SPACT has even been recognized at the global level for proof-of-concept in the use of upconverting nanoparticles in quick response (QR) codes, printed with B9Creations technology in a method they refer to as 2.5D printing. These printed upconverting codes – which are invisible to the naked eye but appear under infrared light – can be used to determine authenticity; reducing counterfeiting and maintaining the legitimacy of products that may be protected.

QR codes can hold information on authentication, manufacturer, and more from pharmaceutical packaging to art and currency to protect against counterfeit copies. Only visible under infrared light, the QR codes won’t damage the product and deliver an arsenal of safety hidden on it in plain sight.

“Protecting intellectual property is one of the largest problems of living in a technological age, and it’s becoming more important than ever for businesses, pharmaceutical companies, and the government to guarantee their product’s legitimacy. We’re reducing the threat by using B9Creations’ technology as anti-counterfeiting technology with 3D printed QR codes that are only visible under infrared light to authenticate products.”

Idea to Impact Accelerator

See More Examples of How B9Creations Is Helping Bring Breakthrough Ideas to Life

Beyond Human Touch: Robotic Skin

School of Electrical Engineering, Korea Advanced Institute of Science & Technology

Robotic skin with human-like sensing holds immense potential in robotics, prosthetics, and healthcare. Researchers are leveraging B9Creations technology for pressure sensors on robotic skin to detect blood pulsation to body weight.

A Feasibility Study on 3D Printed Biopsy Needles

Washington State University

To explore the feasibility of leveraging 3D printing to fabricate biopsy needles, researchers at Washington State University are using B9Creations technology to design and test 3D printed biopsy needles with altered tip geometry and complex internal features, designed to improve yield amounts, that cannot be manufactured using traditional methods.

International Space Station

Made in Space

Made in Space is 3D printing in microgravity for use on the International Space Station, expanding extraterrestrial additive manufacturing capabilities to respond to unforeseeable demands of on-orbit manufacturing.

Self-Detecting Structural Damage

Rey Juan Carlos University

Rey Juan Carlos University is 3D printing self-sensing composite parts with electrically conductive, carbon nanotube-reinforced resin to monitor structural health.

Optical Structures

University of Freiburg

The University of Freiburg is 3D printing optical structures by testing different material compositions, which affect optical quality and mechanical flexibility.

Interested in being one of the universities or research labs we partner with?