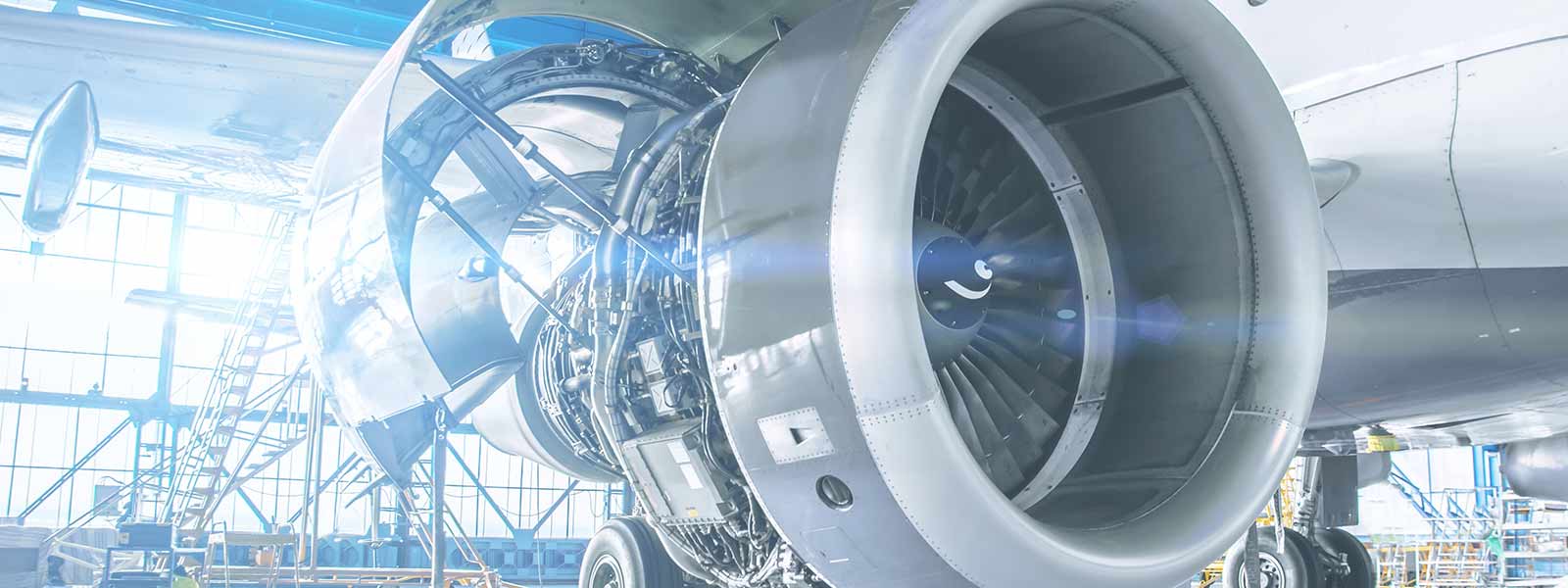

Boost Performance and Reduce Cost with Future-Proof Parts Ready for Flight

Prototype to Production

injection molding

customized parts

Tools, jigs, & fixtures

Material development software

Proven Performance From Prototype to Production

Companies across the aerospace and defense sector are adopting our ultra-precision digital manufacturing solutions to increase speed to market, build more resilient supply chains, and improve production more efficiently and profitably than ever before. Today, we have earned the trust of engineers and manufacturing teams worldwide through digital solutions that deliver proven results and a payback measured in months.

See the solution leveraged by brands from Made in Space to the US Navy Seals, NASA Shared Services, the Naval Warfare Center, 2 of the top 10 aerospace component suppliers, and more.

From New Frontiers to National Defense

Engineered with input from industry experts, our ultra-precision, high-speed additive manufacturing solutions enable you to be more competitive than ever before. Leveraging patented technology, the B9 Core Series 3D printers are precise, fast, reliable, and easy to use.

- Pre-Production - Accelerate iteration, tighten feedback loops, validate function and design

- Customized Production - Boost productivity and build supply chain resiliency with parts on-demand through distributed manufacturing with a secure network of 3D printers

- Production Parts and 3D Printed Injection Molds - Performance materials that open up new revenue streams and reduce costs

- Production Tools - Cut lead time and costs and build custom tooling with materials made for the manufacturing environment to produce high-mix, low-volume parts on the fly

"We did a global search for the right additive partner in preparation to scale up production. B9Creations' hardware, software, custom tailored solutions, and expertise consistently deliver for our business."

Production-Grade Parts. Post-processing To Match.

Through an investment partnership with Mitsui Chemicals, a global leader in healthcare materials, B9Creations launched a new strategic partnership with Mitsui’s subsidiary, SDC Technologies.

With B9Creations biocompatible, design, and engineering resins, healthcare professionals and medical device manufacturers can move from virtual model to print and prototyping to production runs of thousands of parts seamlessly.

Leveraging patented technology, the B9 Core Series 3D printers are precise, fast, and easy to use.

- Out-of-the-box and printing in 15 minutes and never requires calibration

- 4x faster than industry average with <15 to <25 um effective resolution

- Factory startup assistance and lifetime support included

- A robust suite of design, engineering, and injection mold materials

- Intelligent print preparation, management, and monitoring software

- Streamlined workflow with automated cleaning & curing post-processing units

With automated post-processing, you can integrate the end-to-end solution that enables your business to operate more efficiently and profitably than ever before. Simple and fast, the B9Clean and B9 Model Cure let you focus less on process and more on proven results.

See our product guide for all hardware, accessories, materials, software and services.

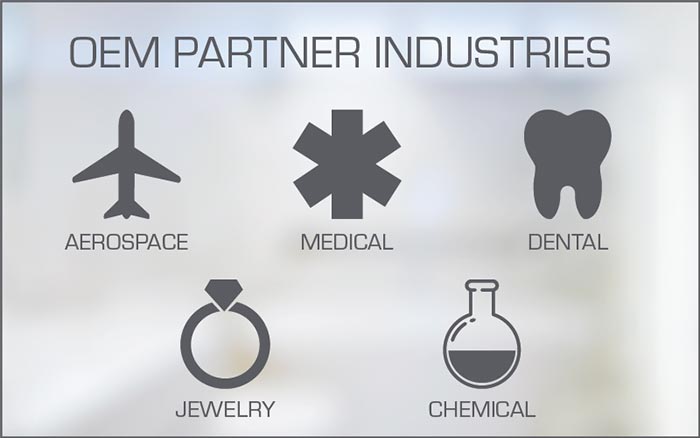

OEM and Strategic Partner Solutions

B9Creations' robust technology and product development capabilities — across hardware, software, materials, and services — deliver customized 3D printing solutions that act as an engine of growth for its OEM customers and allow them to better serve their customers.

We’ve created the only print preparation software that offers industry-specific workflows, intelligent support algorithms, exclusive materials, and custom-built 3D printers for strategic partners in healthcare, aerospace, and other industries where precision is paramount.

On-Demand Manufactured Parts

Leverage our 3D printing service bureau, capable of bringing your ideas to life and revolutionary devices to market faster than ever before - with engineering-grade materials fit for functional testing and that can withstand the manufacturing environment.