3D scanning devices have become some of the most useful tools available, especially when it comes to 3D printing or design. But with each new development that comes out, you can be left wondering which is the best for you. Many companies will throw out flashy specifications such as a high scan resolution or a spec-heavy camera. But is the number of megapixels all that it's cracked up to be?

3D Scanning : More Megapixels Doesn't Mean More Accuracy

3D Scanning : More Megapixels Doesn't Mean More Accuracy

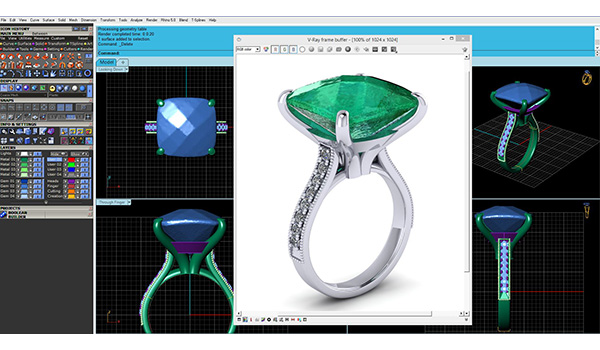

The Ultimate Guide To 3D Printing in Jewelry Businesses

The Ultimate Guide To 3D Printing in Jewelry Businesses

Total Cost of Ownership Guide

Total Cost of Ownership Guide

Bringing Your Jewelry Production In-House

Bringing Your Jewelry Production In-House

Reduce Jewelry Production Costs with 3D Printing

Reduce Jewelry Production Costs with 3D Printing

Five Proven Ways 3D Printing Can Grow Your Jewelry Business

Five Proven Ways 3D Printing Can Grow Your Jewelry Business

3 Ways 3D Printing Increases Jewelry Customer Service

3 Ways 3D Printing Increases Jewelry Customer Service

Gemstone Scanning

Gemstone Scanning

Advantages of Using Rapid Prototyping

Advantages of Using Rapid Prototyping

.png) Engineering Materials

Engineering Materials

The Investment that Pays for Itself

The Investment that Pays for Itself

Why You Should Upgrade to a B9 Core Series

Why You Should Upgrade to a B9 Core Series

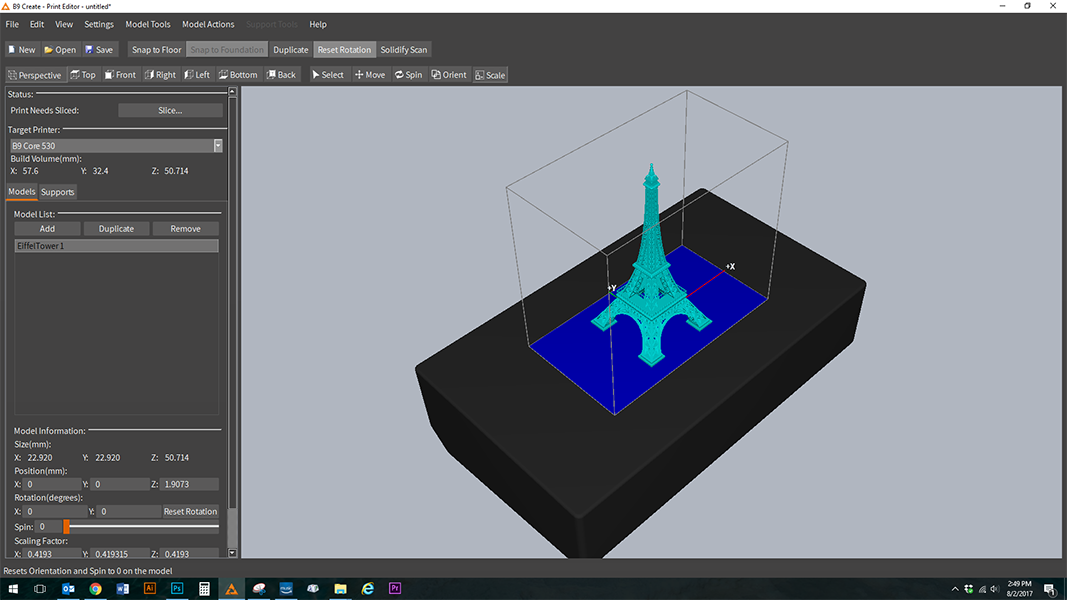

See the Newest Updates in B9Create

See the Newest Updates in B9Create

Breaking The Language Barrier in 3D Printing

Breaking The Language Barrier in 3D Printing

From Robots to 3D Printers

From Robots to 3D Printers

What to look For in a 3D Printer; Resolution, Speed, and Cost

What to look For in a 3D Printer; Resolution, Speed, and Cost

42 Ways B9Create Can Increase Your Productivity

42 Ways B9Create Can Increase Your Productivity

When to Buy a 3D Printer

When to Buy a 3D Printer

Celebrating 5 Years of Innovation

Celebrating 5 Years of Innovation

A Beginners Guide to 3D Printing: DLP, SLA, and FDM

A Beginners Guide to 3D Printing: DLP, SLA, and FDM