Microscale additive manufacturing, or micro 3D printing, is a manufacturing process that uses additive technology to create small, intricate parts ranging in scale from a few microns to several millimeters. This process is becoming increasingly popular due to the growing demand for small, high-precision components used in industries from healthcare to aerospace, electronics manufacturing, and beyond.

The main advantage of micro 3D printing over traditional manufacturing methods, like micromachining and micro injection molding, is its ability to produce complex shapes and features with high accuracy and resolution, without requiring expensive, time-consuming tooling or machining processes. Additionally, micro 3D printing can be more feasible for low- to mid-volume production runs, allows for quick design iterations, and creates less material waste than traditional methods.

Micro 3D Printing Applications

The ability to 3D print tiny things with ultra-high resolution is cool, but where are there real-world applications? Microscale additive manufacturing has enormous potential to transform a wide range of fields – from the healthcare sector to electronics manufacturing, aerospace and defense, and beyond.

-

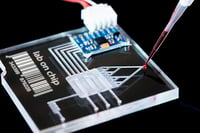

Microfluidics

Micro 3D printing enables the production of complex microfluidic channels, which are used for the precise control and manipulation of fluids. These channels can be used for lab-on-a-chip devices, drug delivery systems, and biomedical diagnostics. With micro 3D printing, these devices can be produced quickly and reliably in-house.

-

Microelectronics

Micro 3D printing allows for the fabrication of complex microelectronic components, such as sensors, microprocessors, and microactuators. These components can be used in a variety of applications, including wearable electronics, implantable medical devices, microchip components, and robotics. Being able to revise prototypes on the fly and reliably produce microscale parts in-house speeds up design development and makes production more efficient.

-

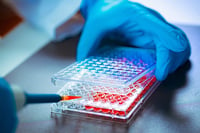

Tissue Engineering

Micro 3D printing has the potential to revolutionize tissue engineering by enabling the production of complex 3D structures, such as blood vessels, organs, and bone tissue, on a microscopic scale. These structures can be used for drug testing, disease modeling, and regenerative medicine.

-

Microscale Optics

Micro 3D printing can be used to fabricate complex optical components, such as lenses, prisms, and diffraction gratings. These components can be used in a variety of applications, including microscopy, spectroscopy, and more.

-

Microrobotics

Micro 3D printing can be used to manufacture microscale robots and devices, which can be used for microsurgery, drug delivery, environmental sensing, and more.

Why Use Micro Additive Manufacturing Over Traditional Microfabrication?

Design Freedom

Additive manufacturing freedom enables precise and intricate designs that would be difficult or impossible to achieve with micromachining or molding techniques. While micromachining is limited in terms of the complexity of shapes that can be produced, micro molding is limited in terms of materials that can be used and the level of detail that can be achieved. Micro 3D printing also enables quick feasibility feedback and allows manufacturers to respond quickly to design changes while avoiding the high cost and complexity of creating new molds and tooling.

Cost Benefits

There are several cost advantages associated with microscale additive manufacturing. In low- to mid-volume production environments, the cost of tooling and setup for traditional manufacturing methods like micro injection molding or micromachining can be relatively high. Micro 3D printing, on the other hand, eliminates the ongoing need to recreate costly molds and tooling. It has a low initial cost and can produce parts without the need for tooling or setup, making it a more economical option. Plus, B9Creations' Elite Micro delivers competitive results at one-fourth the cost of high-end micro 3D printers, making this manufacturing method more economical than ever.

Versatility

3D printing can be easily integrated into the wider manufacturing ecosystem. 3D printers can be used in conjunction with traditional manufacturing equipment, allowing manufacturers to 3D print micro molds for parts that require injection molding approaches.

Material Benefits

A significant amount of the cost of 3D printing is generated by materials, and for standard-size or larger parts, complex support structures may be needed to ensure that the final product is printed correctly, creating material waste that further drives up the cost. Micro parts, due to their size, require significantly less material, so even printing thousands of parts presents a relatively small investment in materials. 3D printing also allows for a wide variety of materials to be used, and switching materials on the Elite Micro is as easy as swapping vats and pressing a few buttons.

Micro 3D Printing Capabilities

Finding the best machine for your needs might be a struggle given the many types of technology available. From micro stereolithography to two-photon polymerization, choosing the right machine for your application can be tough. Having a machine that can reliably and precisely produce the following features is imperative to your design process.

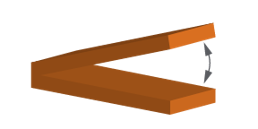

Self-Supporting Overhangs

Overhang angle is the angle between the part and the build table. The closer overhanging features are to being parallel to the build table, the less self-supporting they will be. 3D printing shallower angles can reduce the support material needed, making production cheaper and post-processing easier and faster.

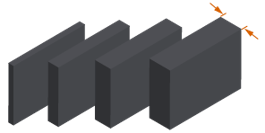

Vertical Wall Thicknesses

Vertical walls are walls perpendicular to the build table. The thinner they are, the less structural integrity they'll have. Having a 3D printer that's capable of reliably producing thin walls is essential for many microscale designs.

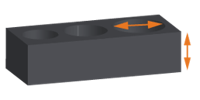

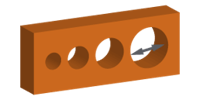

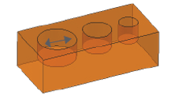

Vertical and Horizontal Channels

These are channels that run all the way through a part in the horizontal or vertical directions. Printing these with precision and accuracy can be imperative for some designs and being able to reliably print these features is a necessity in many fields including micro and millifluidics.

Blind Holes

Blind holes are openings or cavities that, unlike channels, do not go all the way through the part. Printing blind holes of various depths and diameters is essential to design accuracy and precision.

My Parts Are Printed. What's Next?

Post-processing micro parts is a crucial step in achieving high-quality, functional parts. So, how do you clean off the excess resin, which is vital on micro parts where details can easily be lost? And how do you cure these miniature parts without over-curing them, so they don't become brittle and break easily? Fortunately, B9Creations has two automated post-processing units that make this process easier.

B9Clean

Automate your post-processing with thorough, no-mess cleaning. Parts can be transferred directly from B9Creations 3D printers to the B9Clean automated wash unit while still on the build platform or as loose models on the part tray. Keeping microscale components attached to the build table during the cleaning process is recommended to avoid losing them. You can also use a mesh tea ball spoon for contained cleaning.

B9 Model Cure XL

The B9 Model Cure XL has high-intensity 405 and 385 nm LEDs, which allow it to properly cure B9Creations' Clear resin and other specialty materials. It is also large enough that micro parts can be left attached to the build table and placed directly into the curing unit.

Is Micro 3D Printing Right for You?

As technology advances, it'll continue to trend toward miniaturization, pushing the envelope for all avenues of manufacturing and technology. Trying to get ahead of the competition and want more information? Read our comprehensive guide on microscale additive manufacturing!

Download B9Creations' Comprehensive Guide to Microscale Additive Manufacturing

Download the guide now to learn more about how micro 3D printing compares to traditional manufacturing methods (e.g., micromachining and micro injection molding), the cost, design, and material benefits of micro 3D printing, post-processing considerations, and more. Plus, learn more about B9Creations’ new Elite Micro 3D printer platform. With ultra-high resolution, accuracy, precision, and repeatability, the B9 Elite Micro pushes the boundaries of feature size capabilities and delivers even the most challenging micro parts at production quality.

Get more information on:

- Traditional micro manufacturing comparisons

- Micro 3D printing applications

- Cost, design, and material benefits

- Post-processing considerations

- And more!