There are several reasons why micro 3D printing is the top choice for low- to mid-volume production environments. Micro 3D printing, compared to traditional micromanufacturing techniques, is typically more cost-effective, enables quicker iteration and prototyping cycles, offers scalability, and more.

Here are 10 key advantages of Micro 3D printing for low- to mid-volume production environments:

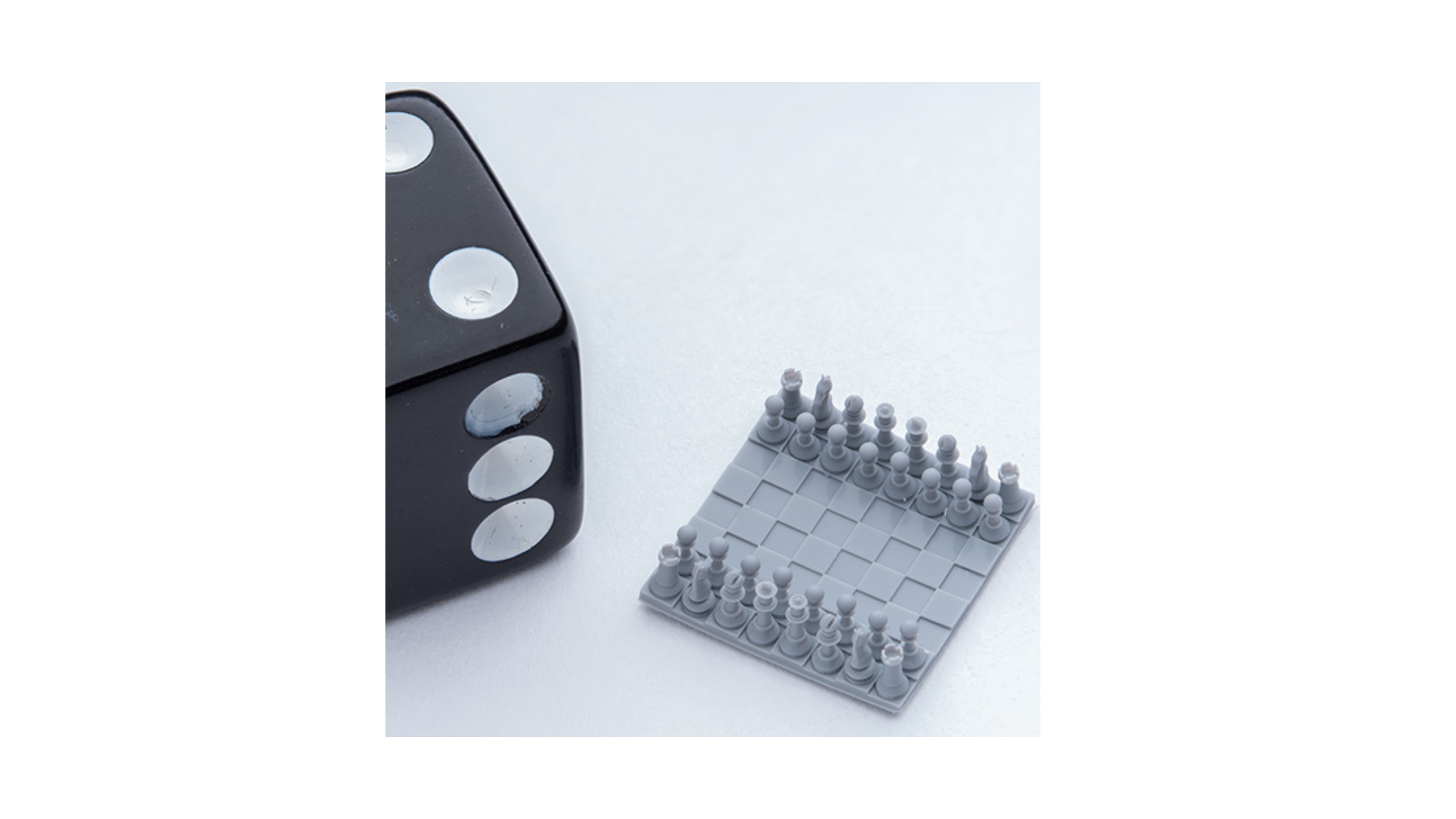

1. Design FreedomMicro 3D printing allows for complex geometries and intricate designs that may be difficult or even impossible to achieve with traditional manufacturing methods. This freedom in design enables the production of highly detailed and precise microscale parts, as well as makes customization in the product development process feasible.

2. Cost-Effective for Small VolumesMicro 3D printing in low- to mid-volume production environments is typically more cost-effective compared to traditional micromanufacturing techniques. Traditional micromanufacturing techniques often involve high setup costs, making them less viable for low- to mid-volume production runs.

3. Rapid Prototyping3D printing enables quick iteration and prototyping cycles. Changes to a design can be easily implemented without the need for new tools or lengthy setup times, reducing time-to-market and speeding up product development.

4. Reduced Material WasteTraditional micromanufacturing techniques often involve subtractive processes, where excess material is removed from a larger piece. This results in significant material waste. 3D printing, on the other hand, adds material only where needed, minimizing waste and optimizing material utilization.

5. Manufacturing Complex AssembliesWith 3D printing, it’s possible to create intricate assemblies as a single, consolidated part. This eliminates the need for assembly, reduces the number of components, and improves overall product reliability.

6. On-Demand Production & Inventory ManagementMicro 3D printing allows for on-demand production – meaning parts can be manufactured as needed, reducing the need for excessive inventory. This can lead to cost savings and more efficient inventory management.

7. Customization & PersonalizationMicro 3D printing makes customization at a micro scale more feasible, allowing for tailored products to meet specific customer requirements.

8. Geographical Flexibility3D printing in-house reduces the need for long-distance transportation and enables decentralized production.

9. Reduced Lead TimesBy eliminating the need for tooling and molds, micro 3D printing significantly reduces lead times compared to traditional micromanufacturing techniques. 3D printing also combines multiple micromanufacturing processes into a single step, streamlining production and reducing the need for assembly. These advantages can be particularly beneficial for time-sensitive projects or industries with rapidly changing demands.

10. Scalability3D printing offers scalability and adaptability, allowing for easy adjustments to production volumes as demand fluctuates.

Interested in learning more? Check out B9Creations' Micro 3D Printing Guide.

Want the Performance of High-End Micro 3D Printers at ¼ the Cost?

Check out the B9 Elite Micro.