B9Creator Print Issues

Print Created by: Joel HrachovecB9Creator Print Issues

If your printer has not been setup, complete the setup process per the Instructional Videos.

Print the Calibration Print (video) and verifying the print is within specification. If the Calibration Print is within specifications the remaining issues in this document can be eliminated. The problem is then typically due to an Orientation and Support issues and/or an Equipment issue.

1. Build Table not calibrated - re calibration required for each Vat and resin change.

2. Vat PDMS (video) is not level, cloudy or torn. If you recoat Vats please cure at 150°F for one hour and let set at room temperature overnight prior to use.

3. B9 Resin issue; not mixed prior to each use and/or used resin – use a new bottle of Resin.

4. Printer Manager (video) - “Current Configuration” not set for the correct Material and/or Z microns.

5. Warped Build Table – Red build tables can warp as the bolts are tightened down to attach to the arm. Check flatness with the edge of a metal ruler after attaching to the arm. We recommend using the Stainless Steel Build table.

6. Sweeper plate positioned incorrectly. Top metal bend points to the right. Sweeper installed from the left side (see pic below).

7. Red Slide Plate sticking (located underneath the Vat) – Clean inside rails with Isopropyl alcohol.

8. Projector Issues. If prints are complete and you are experiencing size and/or detail issues complete the following.

a. Calibration (video), or written Calibration Instructions.

b. Tuning (video), or written Tuning Process.

9. Print Setup

a. Incorrect material and slice selection?

b. Incorrect Resolution settings?

c. Lens cover on projector?

10. Vat in wrong position, PDMS not positioned over open window.

12. Horizontal lines in prints.

a. Insufficient Build Table attachment (Supports), especially at lower levels on the model allowing the print to move.

b. Z axis motor screw rod bent causing Build Table to wobble. Check Z Axis motor issue.

c. PDMS not flat causing Build Table to jerk when sliding. Observe movement during print. Replace PDMS.

13. The remaining possible causes are:

a. Improper model Orientation and/or Support.

b. Print may not be printable.

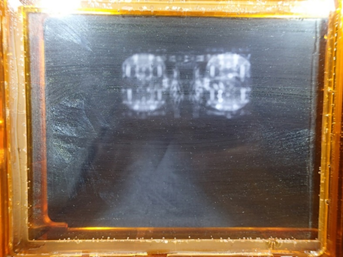

Picture A. Cloudy Vat can cause print failures and must be replaced.

If your issue is not resolved after following these procedures submit a ticket. Include the following information.

1. Take a picture of the Vat window.

2. Print the Calibration Print for the resolution setup from the printer library.

3. Clean per the Post Printing Cleaning Procedures.

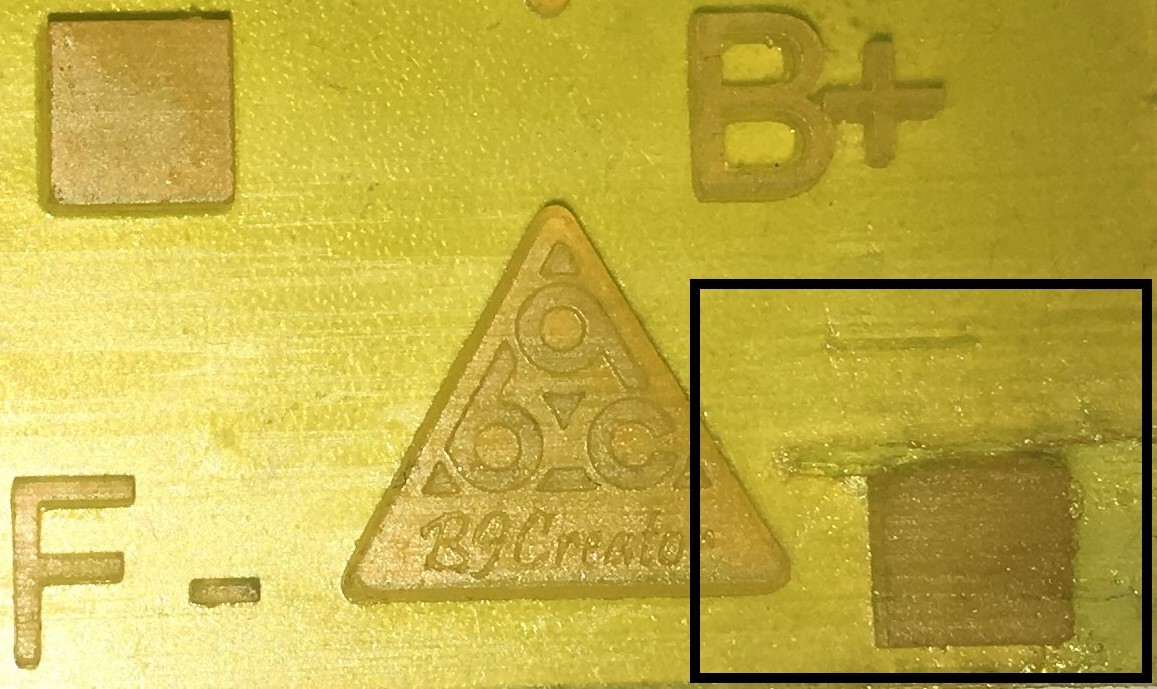

4. Provide a Picture of the Calibration Print with the measurements of the five squares.

5. If the Sample Print is successful, provide clear pictures of your failed prints. Please identify problematic areas clearly and provide to customer support for assistance.

pdf (449 KB)

Updated by Matthew Glover 12/5/2022