B9Creator Build Table Calibration Process

Print Created by: Joel HrachovecB9Creator Build Table Calibration Process

Summary

This document explains the process to calibrate the B9Creator Build Table.

Things to Know

The purpose of the Build Table calibration is to ensure the Build Table rests flush against the clear layer inside the Vat, referred to as PDMS. The red Build Table must correctly make contact with the PDMS layer to ensure the first layer of the print will attach to the table when a print is started. A successful print starts with successful calibrations. For a video tutorial on this process please visit our website at https://www.b9c.com/support/documentation/instructional-videos/build-table-calibration

The Build Table Calibration Process must be repeated any time you switch to a new Vat or recoat an existing Vat. This will account for any variations occurring in the PDMS layer.

Process

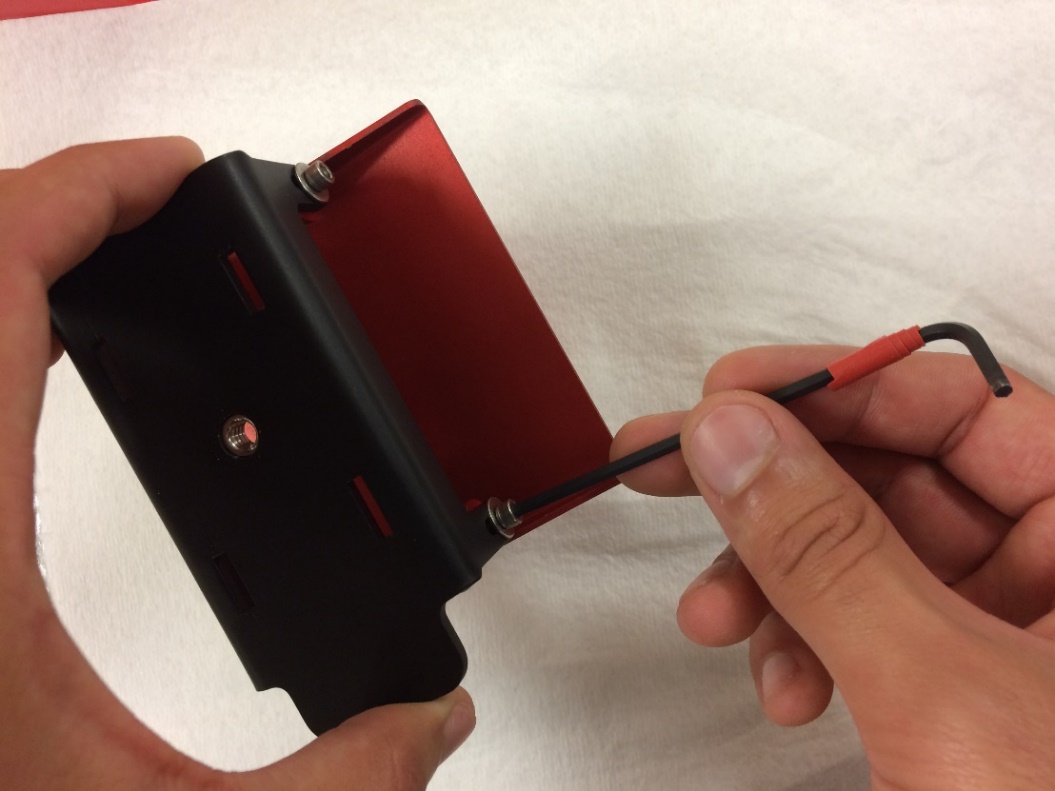

Remove the Build Table from the gold arm by removing the black thumb screw from the top of the gold arm as shown below:

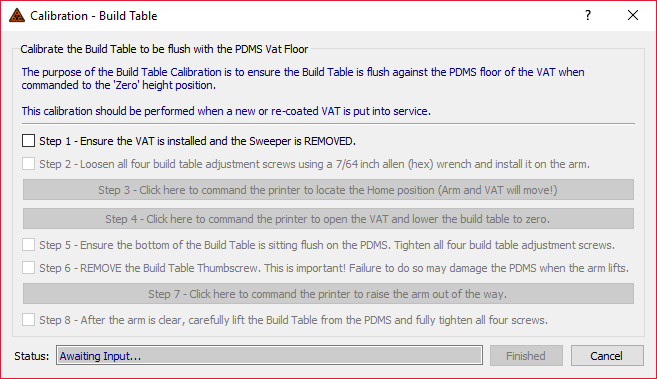

Next, from the Main Menu of the software, go to Settings>Printer Calibration>Calibrate Build Table. The following calibration dialog will appear to guide you through the steps necessary to complete this process:

Step 1: Ensure the VAT is installed, and the Sweeper is REMOVED.

* While it is possible to complete this process while there is resin in the Vat, for best results, we recommend using a clean, empty Vat.

It is very important that the sweeper is REMOVED! If the sweeper is left in, it will damage your PDMS coating!

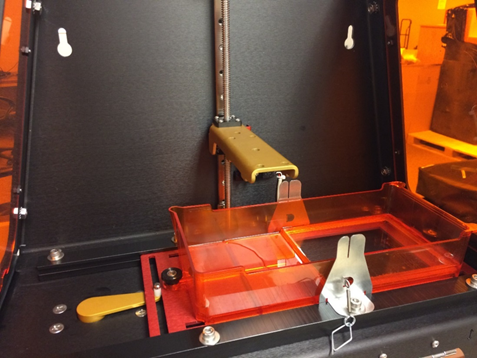

Below is an image of a machine with the Build Table and sweeper removed:

Step 2: Loosen all four build table adjustment screws using a 7/64 inch Allen (hex) wrench and install it on the arm.

The adjustment screws are shown in the figure below:

Do not remove the screws completely. They should be loose enough to allow the build table to slide up and down freely within the black, metal housing. Reattach the Build Table to the gold arm using the thumbscrew. Once attached, verify that the Build Plate is fully extended down, and the thumbscrew is firmly tightened as shown in the picture below.

Step 3: Click here to command the printer to locate the Home position (Arm and VAT will move).

Upon clicking Step 3, the Build Table will find the printer’s “HOME” position. The motors may engage to adjust the position of the vat and build table. When in the “Home” position, the Vat will be positioned with the window to the right side of the enclosure and the reservoir directly over the projector lens. This is considered a closed position. The Build Table will be just above the Vat as shown in the picture above. The B9Creator uses this position as a reference for starting prints.

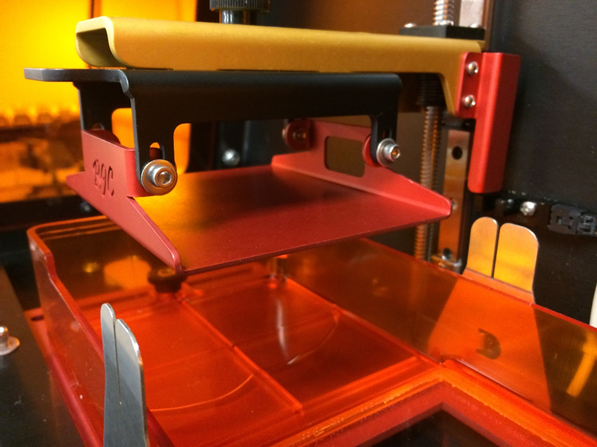

Step 4: Click here to command the printer to open the VAT and lower the build table to zero.

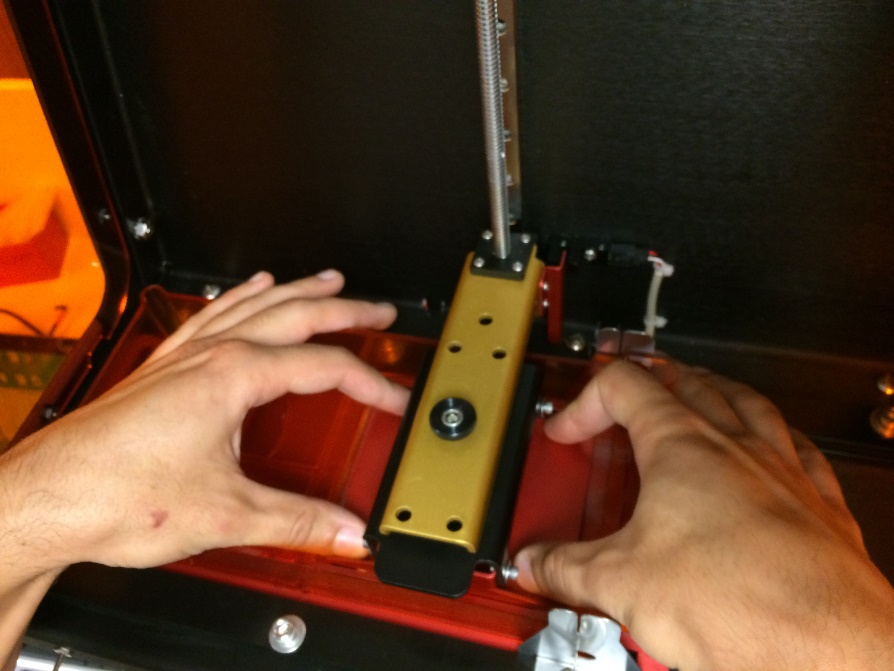

Upon clicking on Step 4, the VAT will slide to relocate the PDMS beneath the Build Table. This is considered an open position. The Z-motor will lower the gold arm, causing the Build Plate to move within the housing until it rests against the PDMS. With the Build Plate resting on the PDMS, apply firm downward pressure with your fingers on the top surface of the build plate, to ensure the plate is fully flush against the surface of the PDMS as shown below:

Step 5: Ensure the bottom of the Build Table is sitting flush on the PDMS. Tighten all four build plate adjustment screws. The screws should be tight enough to prevent the build plate from shifting within the black housing, but not tight enough to cause the build plate to flex.

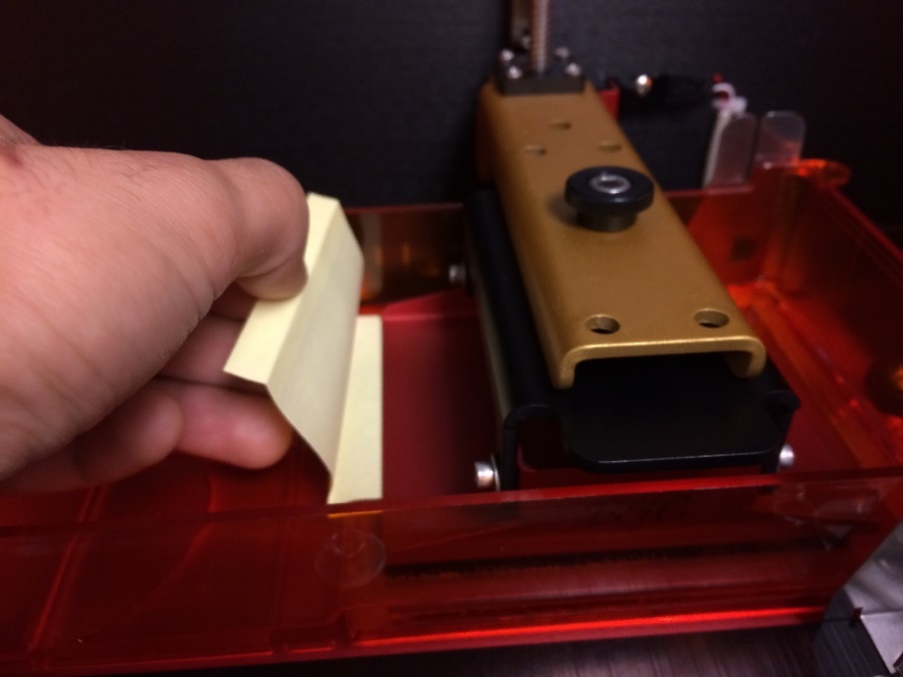

At this point, we suggest testing the contact between the red Build Plate and the PDMS. Using a piece of paper, attempt to slide a corner of the paper between the Build Plate and the PDMS to verify that it can NOT be inserted between the red Build Plate and the PDMS as shown below:

If the build table is not flush, remove the thumbscrew and raise the gold arm using the Z-axis toggle switch. With the gold arm out of the way, gently lift the build table from the floor of the Vat, to prevent damaging the PDMS. (See Step 6) Restart the build table calibration process.

Do not fully tighten all 4 screws currently. Beginning in one corner, begin to slowly tighten the screws 1/8 of a turn, then repeat for the next screw, moving around the build table until all 4 screws are snug, but not completely tightened as shown below:

Check again if the build table is flush. If it is not, loosen the 4 screws once more, apply pressure to it and repeat this step.

Step 6: REMOVE the Build Table Thumbscrew. This is important! Failure to do so may damage the PDMS when the arm lifts.

WARNING: It is important that you remove the thumbscrew before lifting the gold arm. Failure to do so may cause the PDMS layer to separate from the inside of the Vat or otherwise damage the PDMS layer.

Remove the thumbscrew and set it to the side or insert it into the hole in the gold arm near the back of the printer as shown below:

Step 7: Click here to command the printer to raise the arm out of the way.

This step will move the gold arm out of the way to provide clear access to the build table. The gold arm will separate from the build table as it rises.

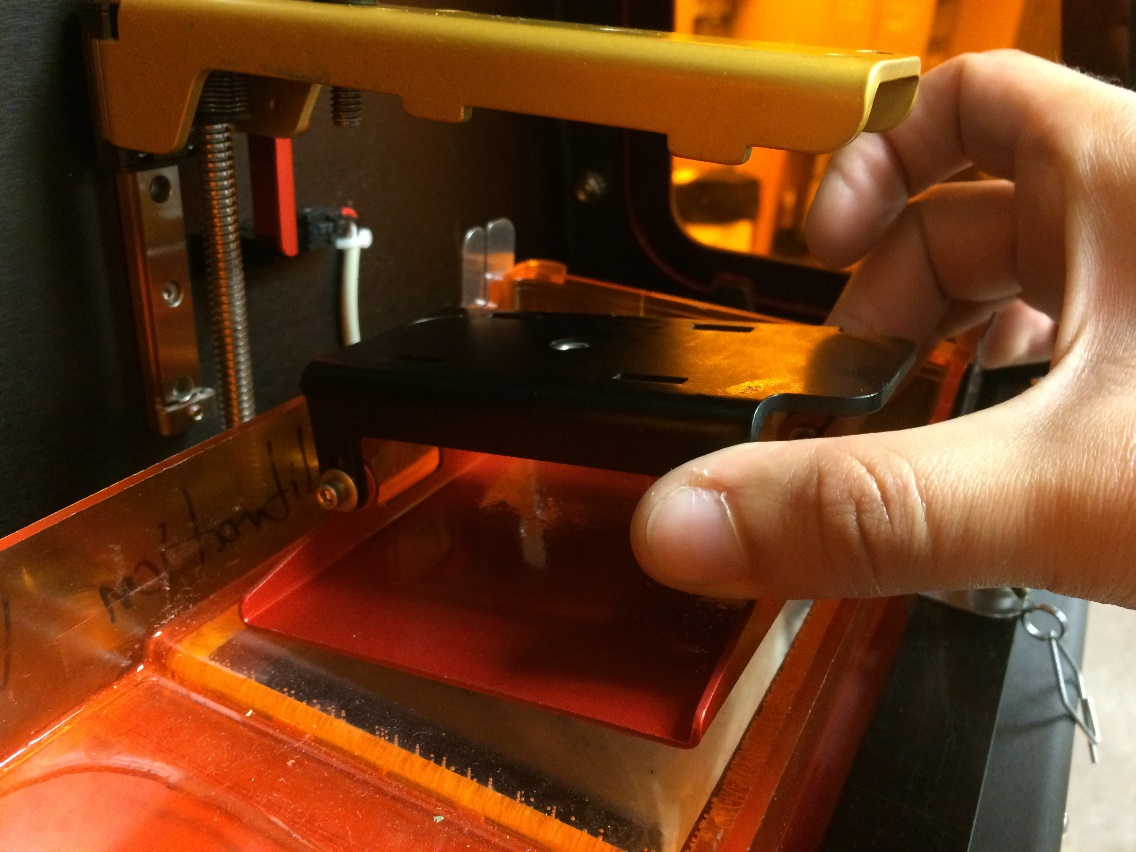

Step 8: After the arm is clear, carefully lift the Build Table from the PDMS and fully tighten all four screws.

To prevent the Build Table from shifting in the housing, apply gentle pressure to the screws themselves as you lift carefully as shown below.

Now finish tightening all the screws. Finally, re-attach the build table to the gold arm using the thumbscrew.

Once the Build Table is attached to the gold arm, you have completed the Build Table Calibration Process.

If you have any questions or comments regarding your B9Creator please submit a ticket to https://www.b9c.com/support-ticket

pdf (972 KB)

Updated by Matthew Glover 12/3/22