B9Model Clean Operations Guide

A quick refresher on how to use the B9Model clean to prepare printed components for curing.

Preparation

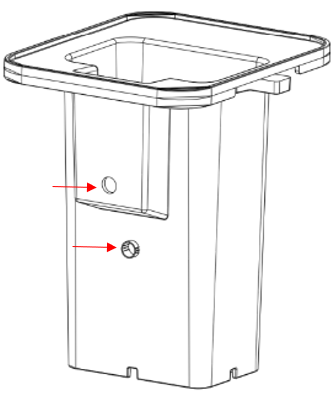

The isopropyl alcohol is held in the outer container of the B9Clean. To fill the B9Clean ensure that the outer container is locked in the base and the inner container and the lid are removed. There are 2 fill lines in the outer container, one at 1.3L and one at 2.0L. If the height of the print is less than 70 millimeters fill the outer container with 1.3L of isopropyl alcohol. If the part is taller than 70 millimeters fill the outer container with 2.0L of isopropyl alcohol. Do not fill the B9Clean by adding isopropyl alcohol directly into the inner container or fill the outer container with more than 2.0L of isopropyl alcohol as this can prevent the inner container from draining completely. If the B9Clean does not fully drain it is possible that the print will be left sitting in isopropyl alcohol for an extended period of time, which can damage the structure of the print. There are two drain plug locations in the inner container, as pictured below.

If the height of the print is less than 70 millimeters place the drain plug in the top hole. If the height of the print is greater than 70 millimeters place the drain plug in the bottom hole. Then place the inner container inside the filled outer container and affix the print with the build table to one of the arms affixed to the lid or place the loose print inside the parts basket. The B9Clean has 2 arms of different lengths to ensure that the print is properly submerged in isopropyl alcohol. If the part height is less than 70 millimeters the long arm should be used. If the part height is greater than 70 millimeters the short arm should be used.

Operation

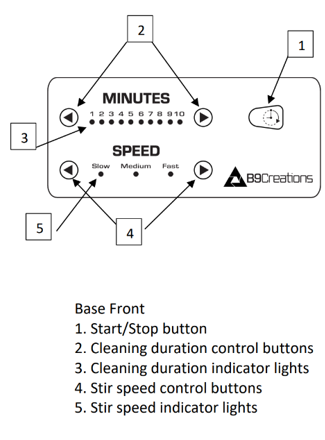

The B9Clean is controlled by the front panel as pictured below.

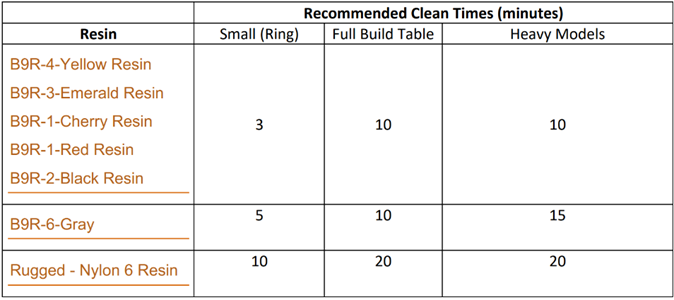

Some prints may require more than 10 minutes to be fully cleaned. However, 10 minutes is the maximum run time of one cycle on the B9Clean. This is because damage can occur to prints that are submerged in isopropyl alcohol for more than 10 minutes at a time. For prints needing more than 10 minutes to clean, simply press the start button again after the first 10 minute cycle has finished. There is no rule for cleaning durations of prints but the recommendations are as follows.

Maintenance

Isopropyl Alcohol:

The most important maintenance that must be done to the B9Clean is regularly replacing the isopropyl alcohol. There is no set time or number of wash cycles wherein the isopropyl alcohol must be replaced. If the isopropyl alcohol begins to look dirty it should be replaced, but ultimately this is up to the operator’s judgement. Isopropyl alcohol is classified as a hazardous material, so consult your local hazardous materials regulations for disposal instruction.

Cleaning:

Any components that come into contact with isopropyl alcohol can be cleaned with water. The B9Clean does not need to be cleaned regularly, but all prints must be washed off before continuing with their post processing. Using either or both water and compressed air to ensure no isopropyl alcohol remains, dries on, or otherwise persists on the prints.