Burnout Schedule and Basic Casting Suggestions.

Burnout Schedule and basic casting suggestions.

Print Created by: Joel HrachovecCasting processes overview video: https://www.youtube.com/watch?v=qHtzjfV2Bjs

Basic tips and advice:

1. Some jewelers will clean up the resin model surface finish with a polishing cloth before casting to minimize wasting precious alloys.

2. Make sure the model is cured and cleaned following B9Creations procedures. Using only >90% Isopropyl alcohol.

3. If casted ring has a cottage cheese texture the resin model needs to be cured longer. Satin cast or plasti cast can be used.

4. Oven needs to be properly calibrated.

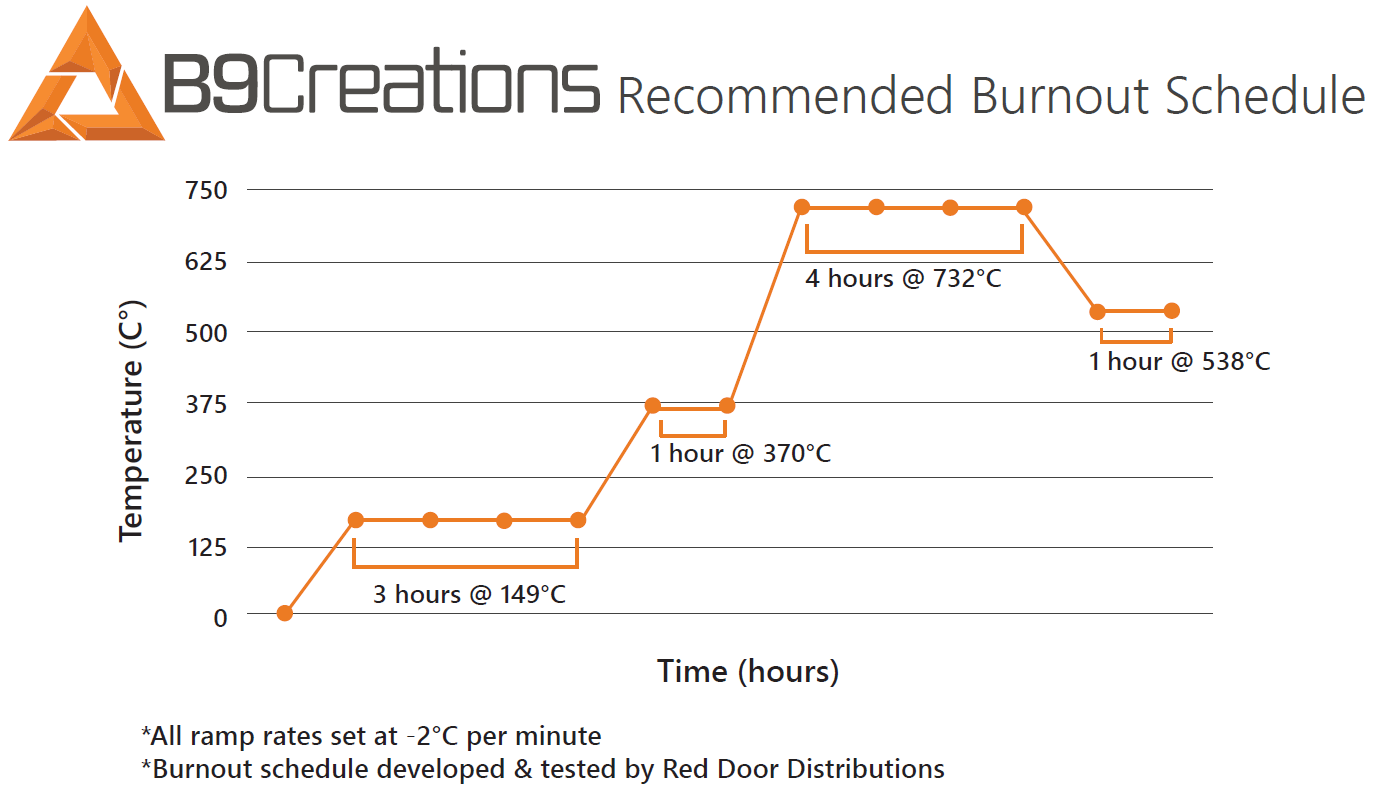

5. Follow B9Creations recommended burnout schedule. If not getting a thorough burnout, change the peak from 732 C (1350 F) for 3 hours to 760 C (1400 F) for 4 hours.

6. We do not recommend casting “stone-in style” where the diamonds are set in the resin model before casting.

Contact B9C if you have casting issues you cannot resolve. We will connect you with an outside casting expert whom can aid in resolving the issue. A cost for services may be requested.

J Joel is the author of this solution article.