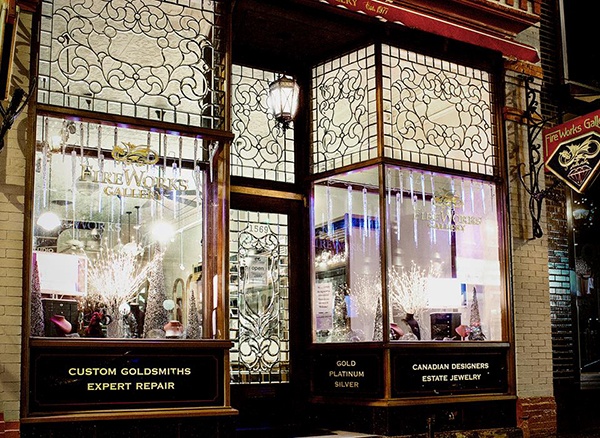

In the port town of Halifax, Nova Scotia, FireWorks Gallery has been operating for 40 years, carrying hand-selected jewelry from artists all over the world and creating their own custom jewelry for customers in-house. FireWorks Gallery prides themselves on offering pieces that are distinctly unique, an aim achieved with the help of a B9 Core Series 3D printer.

Bruce Trick, head designer, CAD artist, and goldsmith, is often found behind the company’s 3D printer, the B9 Core 530.

When Bruce was on the search for a new 3D printer, he knew he was looking for a balance between simplicity and complexity. He wanted a machine that would allow multiple people to use it at multiple customizable settings, while offering an ease-of-use that eliminated the complexities of calibrations and tunings – so he could spend more time designing and creating. Now, both FireWorks owner Judy Anderson and Bruce operate the B9 Core 530.

When Bruce was deciding between machines, it wasn’t just the simplicity of the B9 Core Series that stood out to him, but the accompanying customer service he received.

“It’s your company that I’m very impressed with, not just the machine. The customer service was nothing but impeccable. It’s been amazing. To keep in touch with me through the decision process, that was very nice to have that level of confidence come through the company itself. That’s what brings the whole thing together. You have a belief in your own product.”

As Bruce went through his own process to determine which machine was right for him, B9Creations provided him with the personalized means to do so. He had a custom sample printed, allowing him to directly compare the results from various 3D printer manufacturers.

His results?

Bruce found that “the B9 Core 530 was equal to that of a $35,000 competitor’s 3D printer,” and said that “with the added value of unmatched resolution, inexpensive resin, ease of use, and excellent customer service, they were sold on the Core 530.”

Since the implementation of the B9 Core 530 into the FireWorks Gallery workflow, they’ve saved an average of 30 hours a week on setup, printing, and cleanup.

Because of the B9 Core 530, Bruce and his team can produce unique pieces like this one – and know that they’ve got a company to back them up whenever they have questions or concerns.