Neugebauer’s Fine Jewelry is a historic jeweler located in the heart of the Midwest, specializing in a variety of custom requests and repairs. Frustrated by the delays caused by their old methods of milling, Neugebauer’s invested in the B9 Core 530 for its speed, ease-of-use, and value. Find out how this local jeweler drove profits and growth with the best 3D printer for jewelry casting.

Located in downtown Rapid City, South Dakota, Neugebauer’s Fine Jewelry has been a family owned and operated full-service jewelry store since 1945. Serving western South Dakota, Nebraska, and Eastern Wyoming, custom jewelry designer Mike Baumann sees customers with a wide variety of jewelry needs, from jewelry repair to custom requests. The classic building where Neugebauer’s operates sits on a busy street corner in the middle of downtown, but once you walk in, the busyness fades away and you’re met with friendly smiles ready to help you find (or design) your perfectly dazzling jewelry piece.

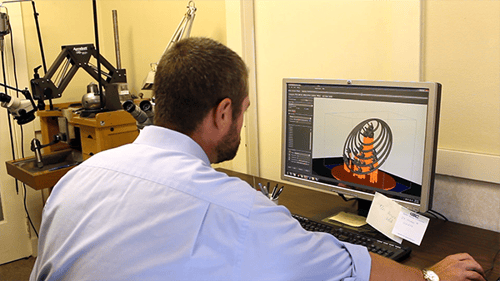

Up a flight of private marble stairs, Mike and a few of his full-time workers have moved on from their old methods of milling custom jewelry onto the newer, more efficient, and more affordable methods of 3D printing. Mike’s B9 Core 530 occupies a small section of a work desk, but easily makes up for it with its production capabilities.

Using the old method of milling, Neugebauer’s was faced with too many complexities. Often Mike would create a design, but the mill wouldn’t be able to produce the right results because of certain limitations. The machine didn’t present the detail he was hoping for, and he was always 3 days behind, even if he was milling all day every day.

Mike hoped to address these limitations as he began looking into the possibility of using a 3D printer. His biggest concerns were the mill’s constraints on time, size, and details.

The B9 Core 530 popped up on Mike’s radar through the GemVision Forum, appealing to him with claims of speed, simplicity, and value that were confirmed once he began communicating with B9Creations.

Mike says he went from a guy who’s never seen a 3D printer printing, to being able to print whatever [he] want[s] within two to three weeks of practice,” all because of the B9 Core Series’ functionality and ease of use. The B9 Core 530 enhances the local jewelry business’s competitive advantage by allowing Mike and his team to spend more time on the sales floor, creating customer relationships rather than spending hours creating models.

Neugebauer’s can print a model while customers explore Rapid City’s historic downtown, and welcome them back in less than an hour for design verification. And if Mike’s out of the office? The machine is easy enough that Mike says “anybody in the store can operate it too.”