When a new product idea has the potential to simplify, modify, or improve the current market, (like when B9Creations emerged in 2011!), that idea shouldn’t just stay an idea. It needs to be conceptualized, analyzed, iterated, and finalized so it can be brought to market sooner and get started changing the world.

These stages of design, conception, and iteration should undergo rapid yet rigorous testing, so you know without a doubt that your new product will launch successful the very customers you want to target.

That’s where prototyping comes in.

3D Prototyping Parts

By creating a functional part that looks and acts like a real end-use part, an idea comes to life and you have a tangible proof of concept.

Rather than piecing together a prototype from whatever materials you can find in your desk drawer, engineers and inventors can now have an exact replica of their new product idea – in their hands.

3D prototyping allows your organization to be agile, incorporating customer feedback instantly into your design, allowing for customization and minimizing design flaws prior to mass production. And you'll save time and money, effectively eliminating the resources required to develop molds or the waste produced from conventional prototyping methods such as CNC machining.

With each iteration, your design improves, building confidence for both the designer and the end customer - while helping identify the actual needs of the market. In short, you'll take a competitive product to market with a shorter lead time and higher acceptance rate.

3D Prototyping Tools

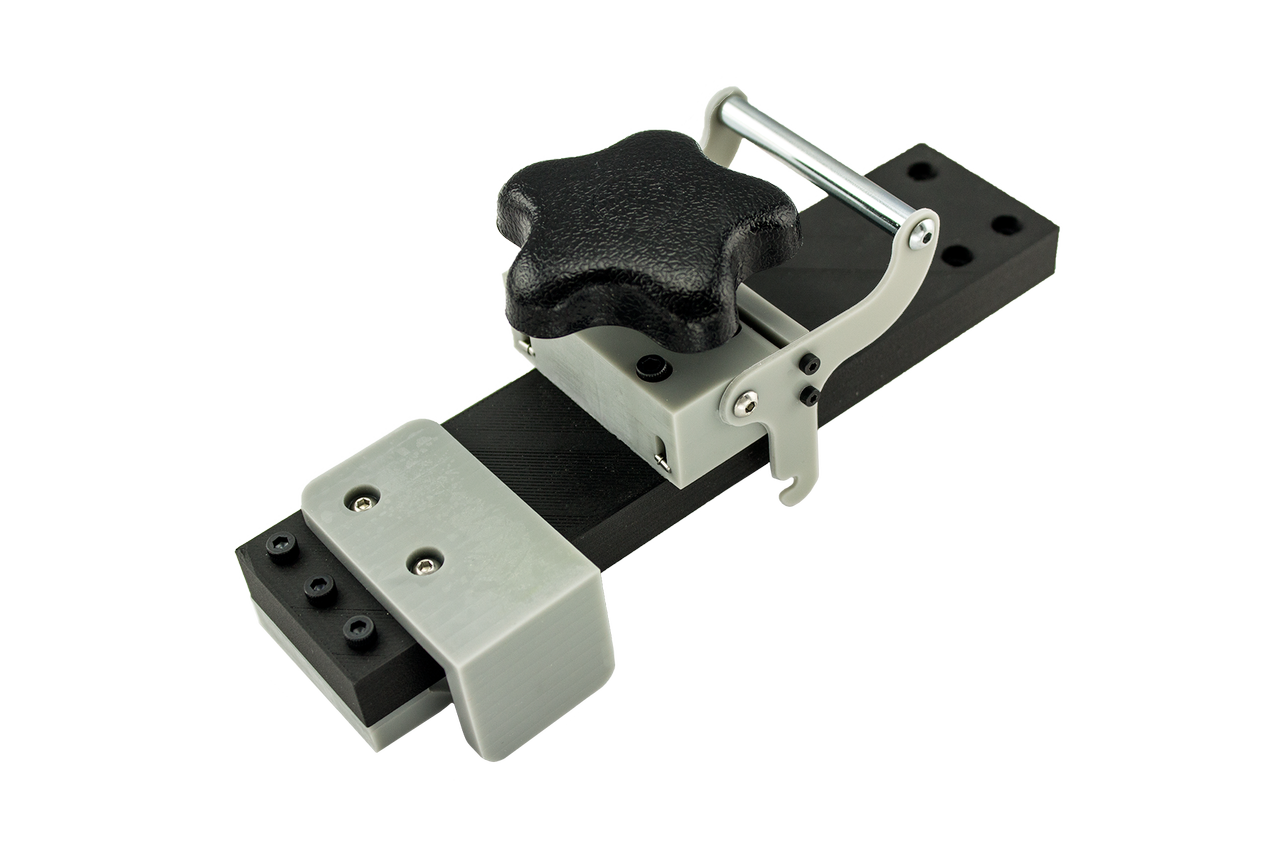

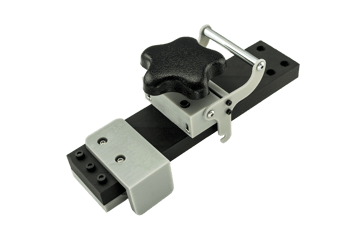

3D printers aren’t only useful for prototyping new concept and products, but can also help you actually take those prototypes into end-use applications. Take this calibration tool for example.

Calibration is a necessary, yet sometimes underrated part of ensuring that a product or part will (in simple terms) do what it’s supposed to do, and do it right. And if a calibration part isn’t correct, then what?

Prototyping tools for in-house use with a 3D printer, especially the B9 Core Series, can make a huge difference in your production capabilities.

This particular part took 3 prototypes spanning over the course of a few days, allowing the user to test out the form, fit, and function and decide if that particular design would work for what they needed. Bypassing an expensive, manual, and time-consuming process (with many touch points), they found their answer and perfected the designs – before they printed the final-use part or spent hundreds to have the parts made. Now, they can guarantee that each part that comes out of their factory will be correctly calibrated, with no human error.

Features that are Necessary for Prototyping

Threaded Screws

Sometimes it’s impossible to fit everything you need on a build table – or you need parts that can be moved or connected. By adding screw threads to your 3D print, this becomes possible. Whether it be with an insert, 3D printed threads, or 3D printed pockets.

Snap Fit

In a similar way, snap fit parts can allow multiple parts to be connected even without screws or glue. By 3D printing snap fit parts, you can save time, money, and resources.

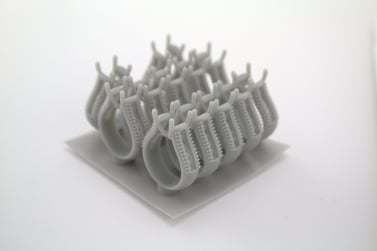

3D Prototyping for Jewelry

When many people think about prototyping, they probably associate it with manufacturing. But 3D prototyping, or design verification, can also fit into a jeweler’s workflow.

Custom jewelry is one of the many ways you can incorporate your own ideas and sentiments into a piece, and has become easier than ever with the dawn of 3D printing.

A jeweler or designer can create a mock-up of their design – and show it to their customer immediately. Leads become customers quicker than ever before - or in the case of one jeweler, a $15,000 job is done in a day.

Before precious metals, especially metals like platinum, are casted, jewelers can be sure that their designs are exactly as the customer imagined.